ISO9001 (2015), ISO14001, ISO13485, Certified.

WhatsApp: +86 138-2620-9144

Email: quote@yokan-machining.com

Yokan delivers expert metal CNC machining services for prototypes and production parts. We combine advanced technology with rigorous quality checks to produce components that meet the highest standards of accuracy and reliability.

● 30% More Value: Western-quality precision at a significantly reduced cost.

● Speed When It Matters: Standard turnaround in 15 days; urgent 5-axis projects in 3-5 days.

● 100% Material Guarantee: Certified materials verified by laser spectrum analysis for total traceability.

Need a Reliable Machining Partner?

Get a competitive quote and lead time in hours.

Home/Material/Metal CNC Machining

Your mission-critical parts demand absolute precision. As providers of CNC machining for metal parts, Yokan specialize in precision machining, we deliver the high-tolerance accuracy your designs require for performance, safety, and reliability.

We combine advanced CNC technology—including 5-axis milling, EDM (electrical discharge machining), and laser cutting—with deep engineering expertise. By employing optimized machining parameters and specialized tooling, we achieve the exceptionally tight tolerances that other shops can’t.

Trust Yokan to transform your complex designs into perfectly machined reality, from prototype to production.

Selecting the right metal is crucial to the success of any metal CNC machining project. The material must meet specific requirements such as high-temperature resistance, structural integrity under pressure, corrosion resistance, workability, cost, weight, and visual appearance. Choosing the appropriate metal ensures optimal performance, durability, and functionality of the final part.

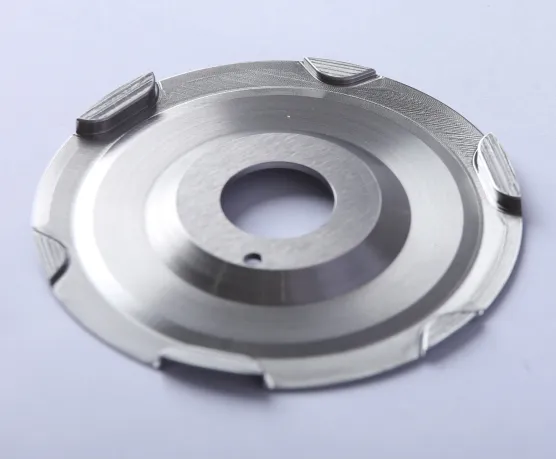

CNC machined metals are utilized across major industries including aerospace, automotive, medical, and more. Below are the metal alloys that Yokan supports for producing complex prototypes and low-volume production through on-demand custom manufacturing.

Aluminum is one of the most cost-effective metals for CNC machining. In addition to its affordability, it offers an excellent strength-to-weight ratio and high performance, making it a preferred choice for lightweight parts. Its high machinability allows for efficient and economical production of components.

Common grades of aluminum used in CNC machining include:

This is the most widely used aluminum grade in CNC machining. It is economical and offers excellent machinability, workability, and resistance to atmospheric conditions. However, it has low resistance to saltwater and chemicals. It is ideal for construction materials, aerospace components, and transportation equipment.

This high-strength aluminum grade is known for its durability, ductility, and fatigue resistance. It is commonly used in high-stress applications in the automotive and aerospace industries.

Among the 6000 series aluminum alloys, 6082 offers the highest strength, surpassing even 6061. Its strength is attributed to its manganese content, which refines its grain structure. It also provides excellent corrosion resistance, making it suitable for aerospace and defense applications.

Explore more >

Stainless steel offers good machinability and is an affordable alternative for CNC machining. It is known for its strength, corrosion resistance, and versatility across various applications.

Common grades of stainless steel include:

One of the most commonly used stainless steel grades, SS304 offers good formability and weldability. It is widely used in kitchen utensils, appliances, and food-handling machinery.

This grade provides excellent corrosion resistance and durability, making it suitable for gears, shafts, bushings, nuts, bolts, and aircraft fittings. It contains 17% chromium, 8% nickel, and 0.15% sulfur, which prevents hardening through heat treatment.

SS316 is known for its exceptional corrosion resistance and strength, owing to its molybdenum content (2-3%). It is commonly used in aerospace and medical implant applications.

Explore more >

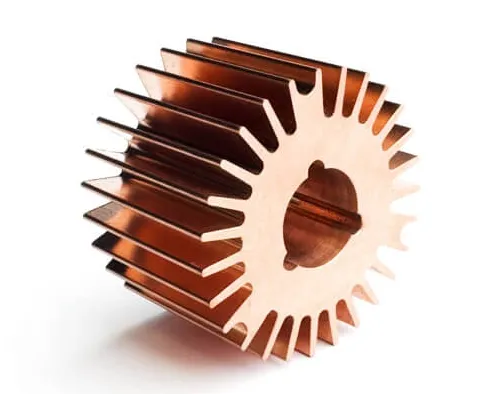

Copper is highly valued for its excellent thermal and electrical conductivity, making it ideal for electrical components. Although it is more expensive than other metals, its high machinability makes it a practical choice for specialized applications.

Explore more >

Brass, an alloy of copper and zinc, offers high machinability, tensile strength, and thermal and electrical conductivity. It is naturally resistant to saltwater corrosion and retains its properties at low temperatures. Its workability allows for aesthetically pleasing finishes. However, its medium hardness and higher cost can increase machining expenses. It is commonly used in electrical systems, plumbing, automotive parts, musical instruments, and medical devices.

Explore more >

Titanium stands out for its exceptional strength-to-weight ratio, temperature resistance, and chemical resistance. Its high strength and biocompatibility make it ideal for medical devices, aerospace components, and high-performance automotive applications. However, its high raw material cost makes it an expensive option for machining.

Explore more >

Our engineering team is here to help. Send us your part design and requirements, and we’ll recommend the optimal material and manufacturing process for performance, cost, and lead time.

Upload Your Drawings for a Free Design-for-Manufacturability Review

01 Upload Your CAD File

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

02 Quote&DFM Analysis

Within 12 hours, we’ll send back the Design For Manufacture analysis and real-time quote.

03 Start Production

Once the order is confirmed, we’ll start the manufacturing process with your CAD design.

04 Get Your Parts

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

Selecting the optimal material is one of the most critical decisions in CNC machining. The right metal directly impacts the functionality, durability, and cost of your final part. A well-chosen material ensures the perfect balance between performance, aesthetics, machinability, and budget.

At Yokan, we help you navigate these choices to find the most efficient and effective solution for your project. Consider the following key factors to guide your decision:

The intended use of your CNC Machined Parts dictates its necessary mechanical and chemical properties.

● Strength & Durability:

Will the component face high stress, impact, or constant load? Alloys like Stainless Steel or 7075 Aluminum offer high tensile strength for demanding applications.

● Strength-to-Weight Ratio:

For industries like aerospace and automotive, reducing weight without sacrificing strength is paramount. Titanium and Aluminum are excellent for achieving this balance.

● Operating Environment:

Will the part be exposed to moisture, chemicals, extreme temperatures, or corrosive agents? Stainless Steel (e.g., 316) and Titanium offer exceptional corrosion resistance for harsh environments.

● Yokan Insight:

Define the operational demands first. This will narrow your choices to metals engineered to perform under those specific conditions.

The ease with which a metal can be cut—its machinability—is a primary driver of cost and production speed.

● High-Machinability Metals (e.g., Aluminum, Brass):

These materials cut quickly and easily, resulting in shorter machining times, less tool wear, and lower costs. They are ideal for complex geometries and high-volume projects.

● Low-Machinability Metals (e.g., Stainless Steel, Titanium):

These require slower cutting speeds, specialized tools, and more time, which increases the overall cost.

● Part Complexity:

Intricate designs with tight tolerances naturally require

more machining time. Choosing a highly machinable

metal is the best way to manage cost for complex parts.

● Yokan Insight:

For the best value on complex parts, aluminum alloys often provide the ideal combination of machinability, strength, and light weight.

The desired final appearance and surface quality of CNC Machined Metal Parts can influence the initial material selection.

● Strength & Durability:

Will the component face high stress, impact, or constant load? Alloys like Stainless Steel or 7075 Aluminum offer high tensile strength for demanding applications.

● Strength-to-Weight Ratio:

For industries like aerospace and automotive, reducing weight without sacrificing strength is paramount. Titanium and Aluminum are excellent for achieving this balance.

● Operating Environment:

Will the part be exposed to moisture, chemicals, extreme temperatures, or corrosive agents? Stainless Steel (e.g., 316) and Titanium offer exceptional corrosion resistance for harsh environments.

● Yokan Insight:

Define the operational demands first. This will narrow your choices to metals engineered to perform under those specific conditions.

Need Help Choosing the Right Metal?

The experts at Yokan are here to help you navigate these factors and select the perfect material for your project’s performance, budget, and timeline.

Get a free manufacturability review and quote today. Upload your CAD files and let our engineers provide their professional recommendation.

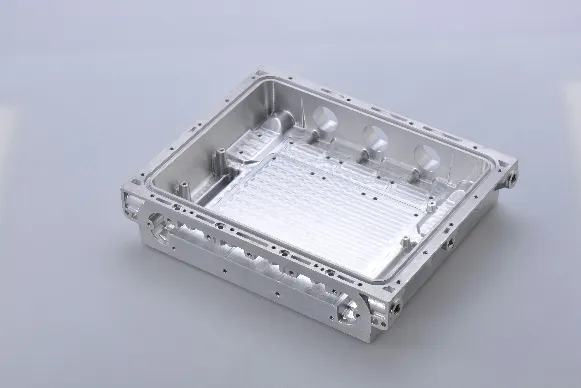

At Yokan, we leverage advanced CNC machining technologies to deliver exceptional precision and quality for metal parts across industries. Our expertise spans a range of specialized processes, each optimized for specific applications, materials, and design requirements. Below, we break down our core capabilities to help you understand how we can bring your projects to life.

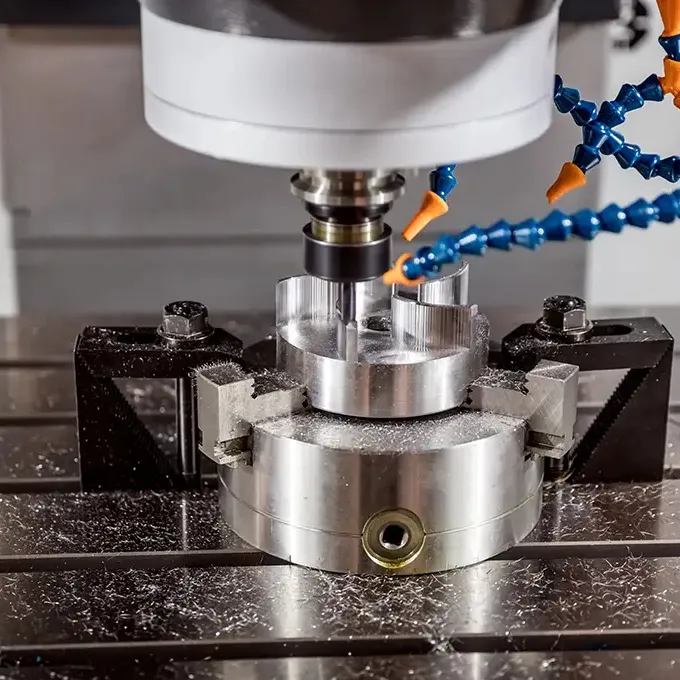

CNC milling uses rotating multi-point cutting tools to precisely remove material from a stationary workpiece. This process is ideal for creating intricate geometries and achieving tight tolerances.

Complex Geometry: Capable of producing detailed 3D shapes, slots, pockets, and fine features.

High Precision: Computer-controlled accuracy ensures consistency and meets strict tolerance requirements.

Material Flexibility: Works effectively with metals, plastics, and composites.

Setup may require more time for highly complex designs.Per-part costs can be higher for large production runs compared to specialized processes.

Engine components, molds, jigs, fixtures, and complex structural parts.

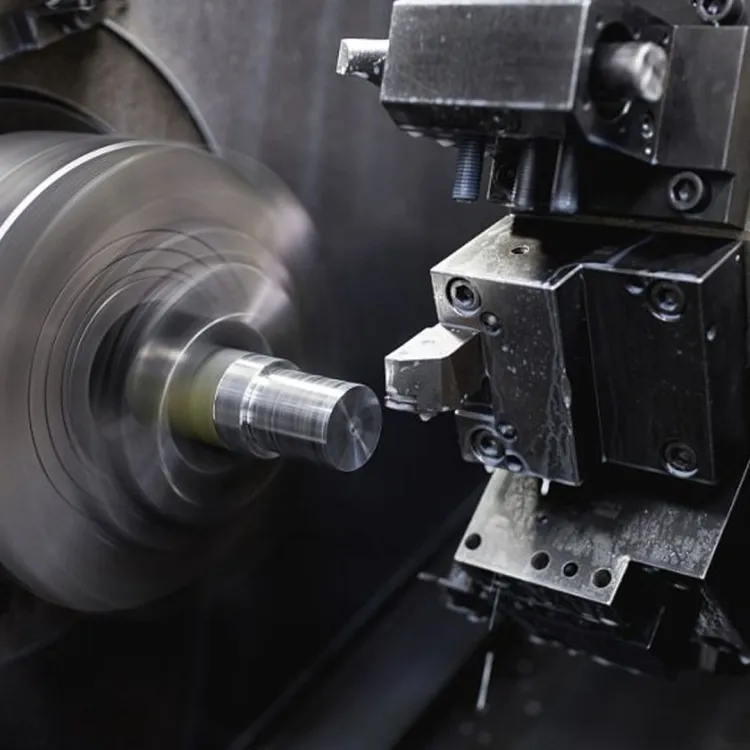

CNC turning involves rotating the workpiece while a single-point cutting tool shapes it into cylindrical forms. This method is highly efficient for producing rotationally symmetric parts.

High Efficiency: Optimized for scalable production of cylindrical parts.

Superior Finish: Delivers excellent surface quality and dimensional consistency.

Cost-Effective: Lower per-part cost for high-volume orders.

Limited to parts with concentric profiles (e.g., rods, shafts, cones).

Less suitable for highly complex or asymmetrical designs.

Shafts, rods, bushings, fasteners, and other cylindrical components.

A fundamental machining operation, drilling creates precise holes in a workpiece using a rotating drill bit.

Critical for parts requiring assembly with fasteners.

Easily integrated into milling and turning cycles for streamlined production.

High-speed material removal for standard hole creation.

Hole depth and precision can be limited by tool geometry.

Often requires subsequent processes like reaming or boring for high-tolerance holes.

Creating bolt holes, ventilation openings, and access points in virtually any machined part.

Boring is a precision process that enlarges and refines pre-drilled holes to exact diameters with a single-point cutting tool.

Achieves exceptional hole diameter accuracy and surface finish.

Can correct misalignment and bring existing holes to strict tolerances.

Requires a pre-existing hole, adding an extra step.

A specialized process that can increase cycle time.

Precision engine cylinders, bearing housings, and any application where hole size and roundness are critical.

Grinding uses an abrasive wheel to remove minute amounts of material, achieving the highest levels of surface finish and dimensional accuracy.

Produces unmatched surface finishes and holds extremely tight tolerances.

Essential for machining hardened steels and other tough materials.

Material removal rate is slow; not for bulk shaping.

Tooling and expertise requirements can increase cost.

Final finishing of tools, dies, bearings, and critical components requiring flawless surfaces.

Tapping is the process of cutting internal threads inside a hole to accommodate screws and bolts.

Creates strong, precise threads for reliable assembly.

A versatile process applicable to most machinable materials.

Requires a accurately pre-drilled hole of a specific size.

Small taps can be delicate and prone to breakage if not handled correctly.

Adding threaded holes for assembly in any component, from small brackets to large plates.

Broaching uses a specialized, multi-toothed tool to machine unique internal or external profiles in a single, linear pass.

Highly efficient for specific shapes like keyways and splines.

Produces excellent surface finishes and consistent profiles.

Custom broaches have high initial tooling costs.

Each broach is designed for a single, specific shape.

High-volume production of internal keyways, splines, and special non-circular profiles.

Sawing is our primary method for cutting raw stock material to size before precision machining begins.

A fast and cost-effective method for cutting bar stock and plates.

Simple setup and operation.

A roughing process only; does not produce finished edges.

Generates material loss in the form of chips.

Cutting raw materials into blanks for subsequent milling, turning, or other operations.

Our engineering team is ready to guide you. We’ll help you select the most efficient and cost-effective machining processes to meet your part’s specific requirements for design, function, and budget.

Contact us today for a free design consultation and quote.

Selecting the right manufacturing partner is critical to the success of your metal fabrication projects. At Yokan, we bring over 15 years of specialized expertise in high-precision CNC machining, serving demanding industries such as aerospace, defense, and medical manufacturing. Our commitment to quality, advanced technological capabilities, and customer-focused approach make us the preferred choice for clients worldwide.

Here’s what sets Yokan apart as your trusted CNC machining partner:

01

We invest in industry-leading machinery from globally recognized brands like Makino, Mazak, and Citizen. This allows us to handle highly complex parts with tight tolerances and sophisticated geometries. Our extensive in-house capabilities ensure we serve as your end-to-end manufacturing partner, reducing lead times and simplifying supply chain logistics.

02

It can be challenging to verify material integrity when working with overseas suppliers. At Yokan, we ensure full traceability and authenticity of all metals used. We provide material certifications and laser spectrum analysis reports, guaranteeing that your components are manufactured to specified standards—even under the most challenging operating conditions.

03

With over 20 years of experience, we’ve developed deep partnerships with top cutting-tool manufacturers such as Fraisia, Hanita, Vidia, and Kenametal. Our expertise in material-specific tooling applications enables superior surface finishes, improved machining efficiency, and cost-effective production—without compromising on quality.

04

Quality is at the core of everything we do. Our 56,000 sq. ft. facility in Dongguan is ISO 9001 and ISO 13485 certified and equipped with advanced inspection technology, including Zeiss CMMs. We enforce strict quality protocols—from raw material checks to in-process validation and final inspection—ensuring every part meets exacting standards.

05

We understand that time is critical. While our standard lead time is 15 days, we offer accelerated 3–5 day turnaround options for urgent prototypes and complex components. Our flexible production model allows us to adapt quickly to your timeline and project requirements.

Experience the difference that technical expertise, advanced technology, and an unwavering commitment to quality can make. Join global industry leaders who trust Yokan for their precision machining needs.

How Much Does Metal CNC Machining Cost?

The cost of metal CNC machining varies based on project specifications, material selection, tolerances, and production volume. While there’s no fixed price, optimizing design for manufacturability (DFM), material choice, and batch size can help reduce costs. At Yokan, we provide competitive, transparent pricing tailored to your project’s unique requirements.

Metal machining is a subtractive manufacturing process where CNC (Computer Numerical Control) machines—such as mills, lathes, and drill presses—precisely cut raw metal into custom parts. Yokan specializes in high-accuracy metal machining using advanced 3- to 5-axis Makino CNC machines, delivering tight tolerances and complex geometries with consistency and reliability.

CNC metal milling uses rotating cutting tools to remove material from a metal workpiece, enabling the production of intricate shapes and fine details. At Yokan, we utilize advanced machinery like the Mazak QTE100MYL, which combines milling and turning capabilities for highly efficient and precise metal fabrication—ideal for complex components machined from single blocks of metal.

● Exceptional Accuracy: Achieve tolerances within fractions of a millimeter, critical for industries like aerospace and medical devices.

● Faster Production: Automated processes enable rapid turnaround without sacrificing quality.

● Minimal Waste: Optimized cutting paths reduce material waste and lower costs.

● Complex Geometries: Produce intricate designs that are impossible with manual methods.

● Broad Material Compatibility: Machine everything from aluminum and brass to stainless steel and titanium.

CNC machines fabricate a wide range of metal parts, including:

● Functional components: bolts, nuts, shafts, gears

● Industry-specific parts: automotive, aerospace, and defense systems

● Custom designs: metal art, engraved signage, and architectural features

At Yokan, we help bring your ideas to life—whether you need prototypes, end-use parts, or low-volume production.

Ready to Start Your Project?

Get a fast, competitive quote and put our expertise to work for you.

Start Your Prototyping & Manufacturing Process with Us in Just 4 Simple Steps

01 Upload Your CAD File

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

02 Quote&DFM Analysis

Within 12 hours, we’ll send back the Design For Manufacture analysis and real-time quote.

03 Start Production

Once the order is confirmed, we’ll start the manufacturing process with your CAD design.

04 Get Your Parts

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

+86 138 26209144

quote@yokan-machining.com

Factory

No.7, Hetang Road, Qingshui’ao,Jian sha zhou, Wanjiang Dist.,Dongguan City, China. 523062

Capabilities

CNC Machining Services

EDM Machining Services

Sheet Metal Fabrication

3D Printing

Parts Finishing

Engineering Services

Inspection Service

Company

About Yokan

Get A Quote

Quality Assurance

Our Blogs

FAQ

Privacy Policy

Service Agreement