ISO9001 (2015), ISO14001, ISO13485, Certified.

WhatsApp: +86 138-2620-9144

Email: quote@yokan-machining.com

Facing challenges with urgent, complex CNC parts or scaling production cost-effectively? Our specialized facilities seamlessly handle orders from 1 to 1,000+ pieces, bridging prototyping to low-volume production.

● 24H Urgent Service: 98% on-time delivery for global emergency orders.

● Capacity: 40+ dedicated CNC machines serving worldwide markets.

● Complex Solutions: Makino simultaneous 5-axis machining achieving ±0.005mm tolerance.

Home/CNC Machining Services

Choose A Reliable Manufacturer

Gain a competitive edge with a rapid-turnaround supplier for your CNC machining projects?

As a leading CNC machining service provider in China, Yokan harnesses 5-axis precision machining, nanoscale EDM technology, Swiss CNC machining, and turn-mill integration to deliver premium-quality complex components – for both prototypes and end-use machined parts.

We offer comprehensive CNC machining services including milling, turning of diverse materials, plus drilling and tapping – establishing us as your one-stop solution partner. Our ISO 9001-certified processes, combined with professional expertise and advanced CNC equipment, ensure your CNC components are precision-made right the first time, every time.

From CNC Prototyping To Low-volume Production

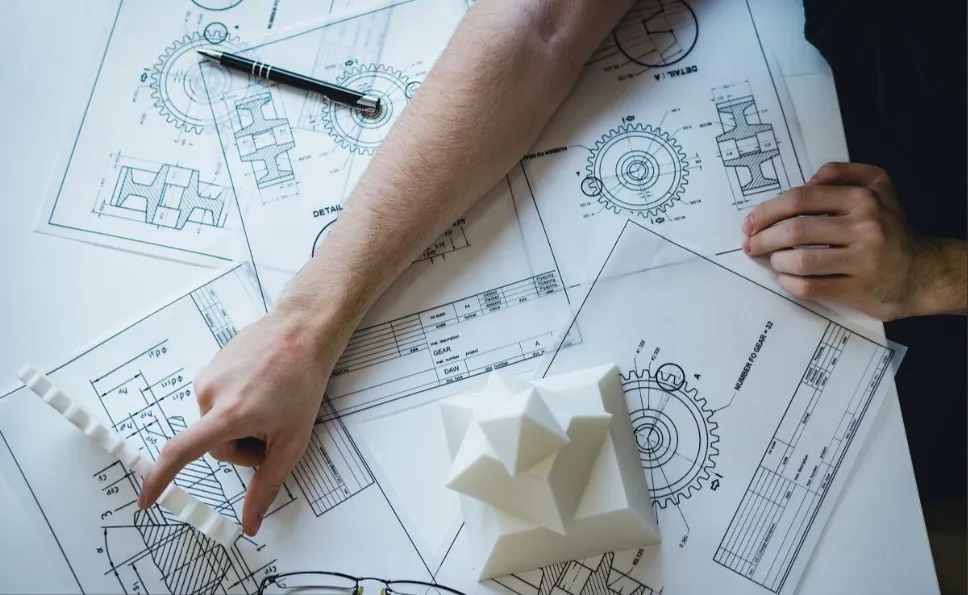

Prototyping creates plastic and metal parts through CNC machining. This enables your design team to accurately simulate final-product appearance, functionality, and material properties. Component testing validates suitability and manufacturability while refining designs.

We deliver professional CNC services guaranteeing quality and precision, backed by rapid turnaround commitments.

CNC machining excels in low-volume custom part production through precision, repeatability, flexible processing, and extensive material options – accelerating product market readiness. Whether custom machined parts or products, our specialized CNC machine shop provides integrated solutions to compress production timelines.

Require 50 to 10,000 custom machined parts? We combine proven capability with cost-efficient CNC machining services.

Our capabilities

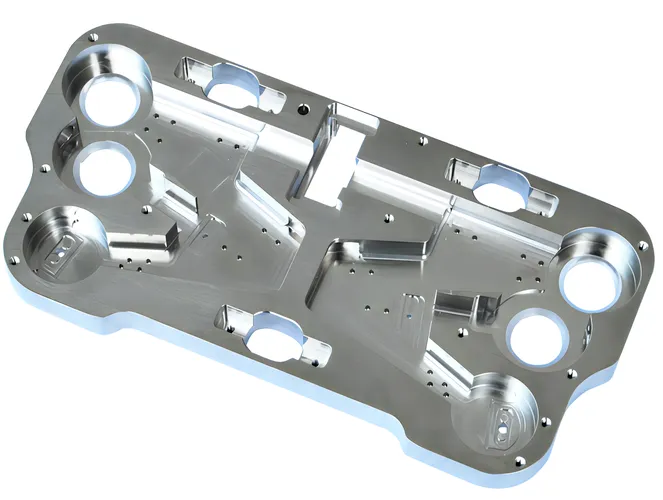

5-axis CNC machining enables complex parts with multi-side features to be machined on up to five faces in a single setup. This delivers significant advantages: better machine utilization, reduced setups and cycle times, and improved quality. The capabilities of 5-axis machining make us more cost-effective for diverse projects of machined components.

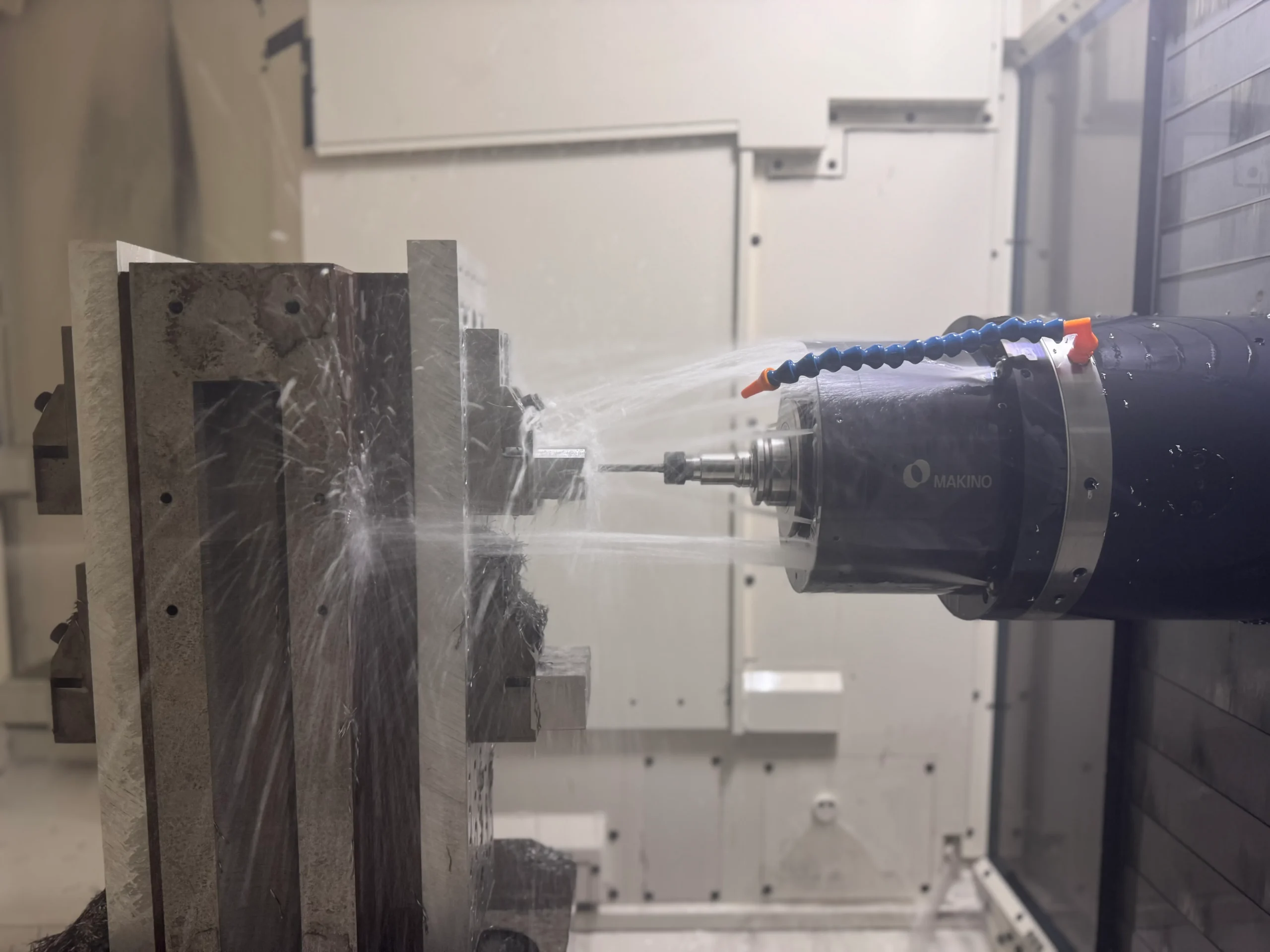

Unlike other CNC shops that modify 3-axis machines with rotary plates, Yokan utilizes state-of-the-art Makino 5-axis centers, including DA300 and D200Z, with true simultaneous multi-axis control.

Need to achieve tight tolerances of ±0.0005″ or better? With proven expertise, advanced CNC technology, and precision inspection equipment, we deliver exceptional accuracy and repeatability, even for highly complex geometry parts. We deliver precision CNC machining services committed to meeting or exceeding customer expectations.

Request a Free Quote >

READ MORE >

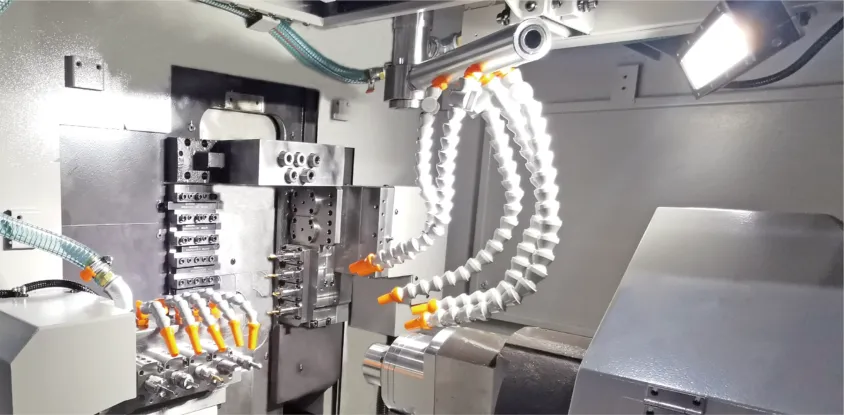

Ideal for medical and aerospace industries that demand intricate parts with tight tolerances and high-volume production, our facility is equipped with 14 CNC Swiss screw machines—including Citizen A20 and TSUGAMI BO205 models—capable of handling diameters up to 1.25 inches (32 mm). This enables us to deliver high-volume production of small, complex Swiss-turned parts with exceptional reliability and precision.

Explore Our Swiss Machining Capabilities.

CNC milling is a subtractive manufacturing process that uses rotating cutting tools to remove material. CNC mills perform cutting and machining operations on various plastics and metals. Suitable for any industry requiring precision components, it’s also ideal for producing precision molds.

What sets Yokan Machining apart is our application of milling: We machine not only square-shaped features but also perform precision thread milling to guarantee threading quality consistency.

READ MORE >

READ MORE >

CNC turning removes material by engaging a precision cutter with a high-speed rotating workpiece, typically creating round or tubular shapes. This process generates complex external geometries and internal features, including threaded holes and profiles.

Beyond standard CNC lathes, Yokan Machining deploys Mazak Turn-Mill Integrex systems that integrate turning and milling in a single setup – reducing machining time while enhancing accuracy.

READ MORE >

The Yokan difference

Precision, Quality and Affordability at any volume. Our team delivers rapid responses to accommodate your requirements.

We achieve ±0.005mm tolerances and produce complex geometries via multi-axis capabilities, leveraging Makino and Mazak CNC systems enhanced by Zeiss inspection technology.

We are proud of our abilities in machining 300+ materials with specialized tooling strategies, including:

●

Stainless Steel (303, 304, 316, 17-4PH, M390)

●

Aluminum (6061, 7075, MIC-6)

●

Titanium (Grade 2, 5, 23)

●

Exotic Alloys (Inconel, Hastelloy, Monel)

●

Engineering Plastics (PEEK, Ultem, Delrin, PTFE, Nylon, Polycarbonate)

Our tooling expertise ensures optimal surface finishes (Ra 0.8μm standard), material-specific chip control, and maximized tool life.

With 15+ years of expertise, Yokan Machining delivers CNC solutions for automotive, aerospace, and medical sectors. Our DFM analysis prevents 90% of manufacturing issues at design phase.

Real-time monitoring and CMM inspection ensure 99.98% first-pass yield. We maintain ISO 9001:2015-compliant processes with comprehensive inspection documentation.

We impose no MOQ restrictions and accommodate made-to-order production from 1 to 10,000 pieces on demand. You receive dedicated engineer support with responses within 12 hours.

Our in-house machine shop operates 24/7, scaling seamlessly from single prototypes to volume production runs of 10,000 units.

CNC machining is a versatile manufacturing technology supporting diverse applications. At Yokan Machining, our precision-machined components demonstrate proven applications across aerospace, automotive, medical, robotics, and consumer electronics industries.

High Performance Machined Medical Components

Machinable Custom Automotive Parts

High Precision Machined Aerospace Components

Metal and Plastic Machining of Consumer Electronics

Low-Volume Machined Parts of End-Use

Yokan provides CNC machining services for over 30 engineering-grade plastics and metals. Various surface finishes can be applied to meet functional and aesthetic requirements.

●

Plastic: ABS, PC, ABS+PC, PMMA(Acrylic), PA(Nylon), PA+GF30, POM(Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI(Ultem), Teflon, Bakelite Resin, Epoxy Tooling Board.

●

Metal: Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy.

●

Finishes: We support one-stop CNC machining surface finishing to meet the visual and functional requirements of any design. Including sanding, sandblasting, mirror polishing, painting, printing, laser etching, anodizing, electroplating, nickel plating, chrome plating, powder coating, etc.

CNC Plastic Machining

Over 30 engineering-grade materials available for CNC plastic machining. Produces fully functional parts suitable for mechanical testing.

Our deep knowledge of every plastic material’s characteristics enables optimized tooling selection and production processes, achieving improved surface roughness, higher geometric accuracy, and reduced machining time.

Learn More About CNC Plastic Machining

CNC Metal Machining

From prototypes to end-use parts, our mastery of CNC metal machining techniques helps us achieve tighter tolerances, faster turnaround times, and more challenging manufacturing projects.

Yokan Machining is renowned for machining complex geometries in challenging materials like Titanium, Tungsten Carbide, and Inconel using specialized tooling.

Learn More About CNC Metal Machining

CNC Machining Tolerances

Yokan adheres to ISO 2768 (medium) for plastics machining and ISO 2768 (fine) for metals. We maintain standard tolerances from ±0.005″ (±0.125mm) to ±0.002″ (±0.05mm). Tighter tolerances require a 2D drawing specifying critical dimensions. Our engineering team will collaborate with you to ensure maximum precision.

Customers We Serve

Yokan Machining delivers world-class manufacturing services to a diverse and rapidly expanding global client portfolio. Our customers span across continents and represent industries ranging from independent inventors and design studios to large-scale industrial, commercial, medical, automotive, and aerospace enterprises. We remain committed to precisely meeting your design and manufacturing requirements, transforming concepts into tangible realities.

+

Clients To Work With

+

Countries Of Operation

%+

Customer Satisfaction

See What Our Customers Say

We are proud that Yokan has become a trusted machining partner for customers right across the globe, but don’t just take our word for it. Have a read through our testimonials below.

“

All of Yokan staff that I have been working with are very professional and great to work with since day one. I have been in charge of Purchasing for over 15 years and worked on many project with suppliers from all over. You can tell when a company has a good product and plan to executes their goals. I watched that progress from the beginning with you folks and I am very satisfied. Thanks again and great job to all of you that we have been working and the others behind the scene.

Director, Supply Chain

“

From the quick, accurate response to our RFQ, to the timely installation at our customers’ facility, Yokan responded with complete professionalism. They handled all aspects of this turnkey quickly, professionally and cost effectively. We look forward to working with them again on future projects.

Purchaser

“

Our customer has decided the yearly move rate, and it will be 4280 pieces per month lasting 24 months for articles 42306466 and 42302687.

We see that we have a little bit of room in the pricing of these parts due to the increased move rate, and we would like to share this with Yokan because of our good partnership. We value a good partnership.

Head of Procurement Operations

Start Your Prototyping & Manufacturing Process

with Us in Just 4 Simple Steps

Upload Your CAD File

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

Quote & DFM Analysis

Within 12 hours, we’ll send back the Design For Manufacture analysis and real-time quote.

Start Production

Once the order is confirmed, we’ll start the manufacturing process with your CAD design.

Get Your Parts

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

24/7 Support for Productions + Prototypes & Parts Fast Global Delivery

We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications. Get the support you need on CNC machining and engineering information by reading the FAQ here.

Yes, we offer custom color anodizing services for CNC-machined parts. By adjusting the type of dyes, electrolytic solutions, and process parameters (e.g., voltage, temperature, and immersion time), we can achieve a wide range of colors, including gold, red, black, blue, green, and bronze, to meet specific design requirements.

For example:Architectural Applications: Custom gold or bronze finishes for luxury buildings.

Industrial Components:Black or gray coatings for corrosion resistance in automotive parts.

Consumer Electronics: Vibrant colors like blue or red for aesthetic appeal.We ensure color consistency through strict control of dye batches, process parameters, and post-anodizing quality checks.

CNC machining is also called computer numerical control machining. We provide the following machining services: milling, turning, drilling, threading, tapping, EDM and wire EDM, custom surface finishing, prototype machining, low volume or one-off part machine runs, modification of existing parts, material sourcing assistance, limited material warehousing, and parts dispatching.

From prototype to production, we offer fast turnaround CNC machining of your custom metal and plastic parts for quantities ranging from 1 to 10,000 pieces, with delivery as fast as 3 days.

Yokan operates a 53,000-square-foot CNC machining facility in Dongguan, China. Our 60+ skilled technicians and 38 high-performance CNC machines enable 24/7 operations, delivering over 300 projects and 30,000+ precision machined parts monthly across our machining centers.

Our engineering and sales teams provide one-on-one quote support for your project. Typically, for similar parts, CNC lathe machining costs 15% less than standard 3-axis CNC milling. In contrast, 5-axis machining costs increase significantly: continuous 5-axis CNC milling typically costs over 20% more than indexed 5-axis machining (also known as 3+2 milling), and roughly double the cost of a standard 3-axis mill. To achieve the most cost-effective CNC machined parts, larger production runs are recommended to amortize the machine setup costs.

Maximum Dimensions (3-axis milling): 1020×520×505 (mm).

Maximum Dimensions (5-axis milling): 560×640×640 (mm), Worktable Diameter Φ350 mm.

After machining, parts exhibit slight visible tool marks known as an “as-machined” or “as-milled” finish. While the industry standard surface roughness (Ra) ranges from 1.6-3.2 μm, we maintain a higher standard of 0.8 μm Ra. Upon request, we can achieve finer finishes of 0.2-0.8 μm Ra, though this requires additional machining time and incurs higher costs.

CNC machining is also called computer numerical control machining. We provide the following machining services: milling, turning, drilling, threading, tapping, EDM and wire EDM, custom surface finishing, prototype machining, low volume or one-off part machine runs, modification of existing parts, material sourcing assistance, limited material warehousing, and parts dispatching.

From prototype to production, we offer fast turnaround CNC machining of your custom metal and plastic parts for quantities ranging from 1 to 10,000 pieces, with delivery as fast as 3 days.

While full part design falls outside our scope as a contract manufacturer, we provide design for manufacturability (DFM) guidance. Through DFM analysis, we work closely with you to optimize designs, reduce production costs, and maintain functionality.

In most cases, we will respond to your quote within 1 business day. The best way to help ensure a quick quote is to provide as much accurate and specific information as possible.

In fact, there is no standard delivery time, as we schedule production based on current workload. After we receive your purchase order, complete documentation, and confirm material availability, we will promptly provide an exact delivery time frame. Typical lead times range from 3 to 10 business days, extending to several weeks for complex parts, urgent requests, or large quantity orders.

CNC machining is also called computer numerical control machining. We provide the following machining services: milling, turning, drilling, threading, tapping, EDM and wire EDM, custom surface finishing, prototype machining, low volume or one-off part machine runs, modification of existing parts, material sourcing assistance, limited material warehousing, and parts dispatching.

From prototype to production, we offer fast turnaround CNC machining of your custom metal and plastic parts for quantities ranging from 1 to 10,000 pieces, with delivery as fast as 3 days.

CNC machining is also called computer numerical control machining. We provide the following machining services: milling, turning, drilling, threading, tapping, EDM and wire EDM, custom surface finishing, prototype machining, low volume or one-off part machine runs, modification of existing parts, material sourcing assistance, limited material warehousing, and parts dispatching.

From prototype to production, we offer fast turnaround CNC machining of your custom metal and plastic parts for quantities ranging from 1 to 10,000 pieces, with delivery as fast as 3 days.

If you require international Quality Assurance, our ISO-9001-certified facility guarantees rigorous standards. Equipped with dedicated inspection tools and skilled QC/QA personnel, we provide 2D reports, CMM reports, or 3D scan reports to verify your parts meet all specifications.

All dimensional tolerances, geometric tolerances (GD&T), and print notes are validated per our MIL-STD-105E statistical sampling plan, targeting zero rejects. Full dimensional inspection reports ship with your completed parts.

Our complete CNC services ensure high quality, competitive prices, and on-time delivery from prototype to production.

+86 138 26209144

quote@yokan-machining.com

Factory

No.7, Hetang Road, Qingshui’ao,Jian sha zhou, Wanjiang Dist.,Dongguan City, China. 523062

Capabilities

CNC Machining Services

EDM Machining Services

Sheet Metal Fabrication

3D Printing

Parts Finishing

Engineering Services

Inspection Service

Company

About Yokan

Get A Quote

Quality Assurance

Our Blogs

FAQ

Privacy Policy

Service Agreement